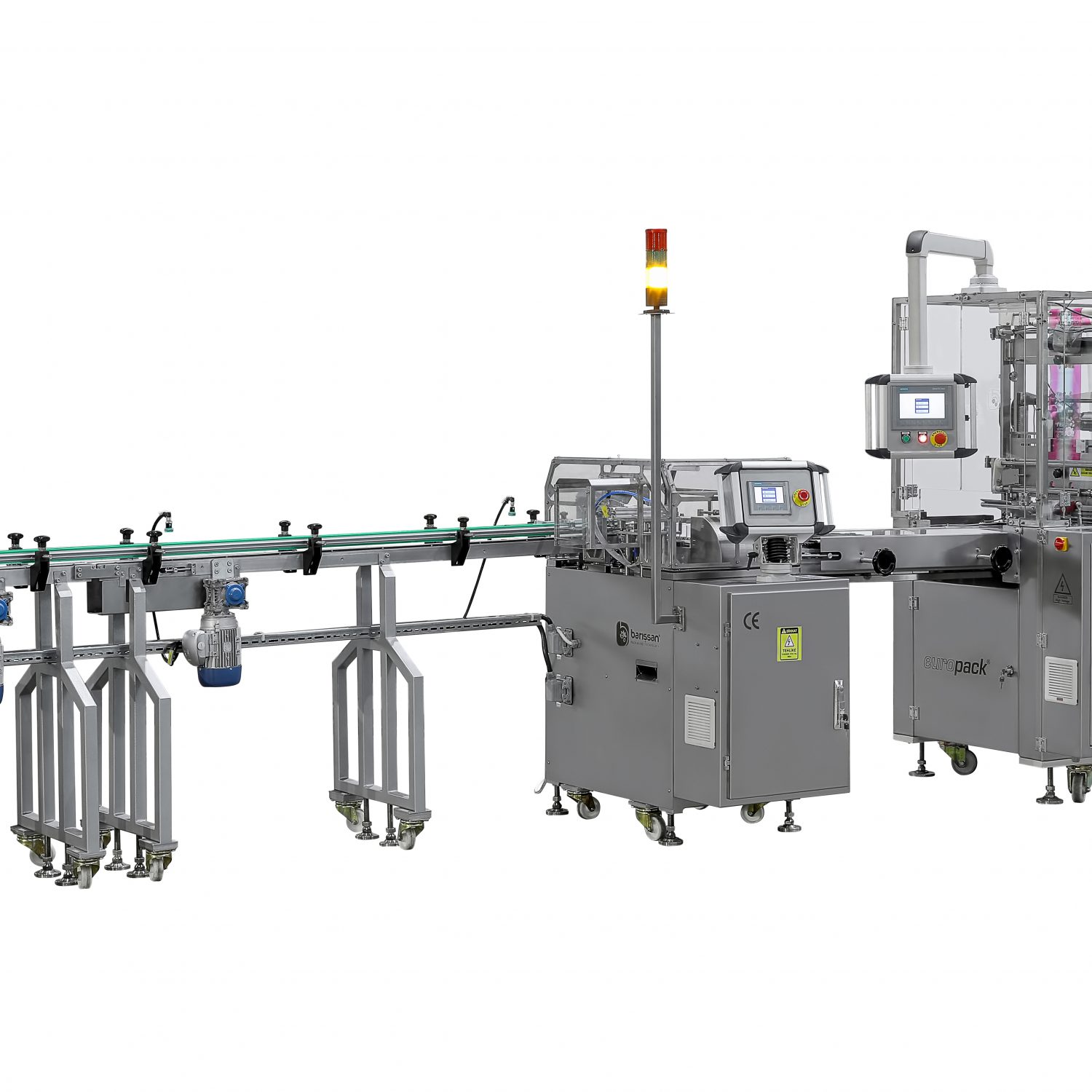

The Europack, is the result of our 40 years of experience combined with the components of high quality European brands, was produced with an understanding of efficiency, durability and quality.

You can minimize your time, loss and energy costs with the hardware on it.

Product feeding is done manually by moving conveyor made of stainless steel.

It provides easy control with PLC automation.

Speed control, temperature controled can be provided by color PLC screen.

Via the easily adjustable motorized format system, the package folding intervals can be changed at specified intervals.

Via reinforced paper cutting system, up to 40 microns thick packaging material can be used.

There wont waste of raw materials in printed packages with photocell system. Because of the electric motor connected to the photocell, the excessive packaging material is rewound.

With CNC machined, heat treated and special oil coated cams, machine movements are provided more easily and provide a long-lasting production.

With special production and heat treated gears, the working parts of the machine work more easily and durable.

All parts in contact with the product are made of AISI 304 quality stainless steel. Thus, it can be used safely in accordance with food production.

With the touch screen with internet connection that allows remote intervention, any malfunction can be remedied by remote assistance.

Through flexiglass covers controlled by safety equipment, manual intervention is easier and possible work accidents are prevented.

Package shape Package Dimensions (mm)

…………………. hmin hmax lmin lmax wmin wmax

Ø Round 25 75 90 245 – –

ÿ Recktangle 15 75 90 245 25 140

Capacity: 35-42 Packages / Minute

Packaging Material Thickness: Min. 25 Micron – Max. 40 Micron

Power Consumption: 2,2 kw

Air Consumption : 6 bar, 200 lt / Minute

Packaging Material: OPP, PP Packaging Material with Heat and Adhesion from A-A and A-B Faces

Maximum Coil Diameter: 300mm

Türkçe

Türkçe Français

Français

Reviews

There are no reviews yet.